There are numerous advantages for your business in having a physical 3D model of your product:

Nothing grabs people’s attention like a physical model they can experience from all angles. Touching and feeling says more than a thousand photographs.

Allow your audience to get a deeper understanding of the features of your equipment. Explaining functional principles is much easier with a 3D model.

A 3D model enables questions and sparks a dialogue between you and your audience in way no other media can do, while showing how invested you are in the product.

The size of your product may make it unfeasible to travel with, for example when meeting with your clients or when attending trade fairs.

PRINTbart specializes in creating 3D printed assemblies with a high degree of detail which facilitate a better understanding of the functionality and features of your equipment.

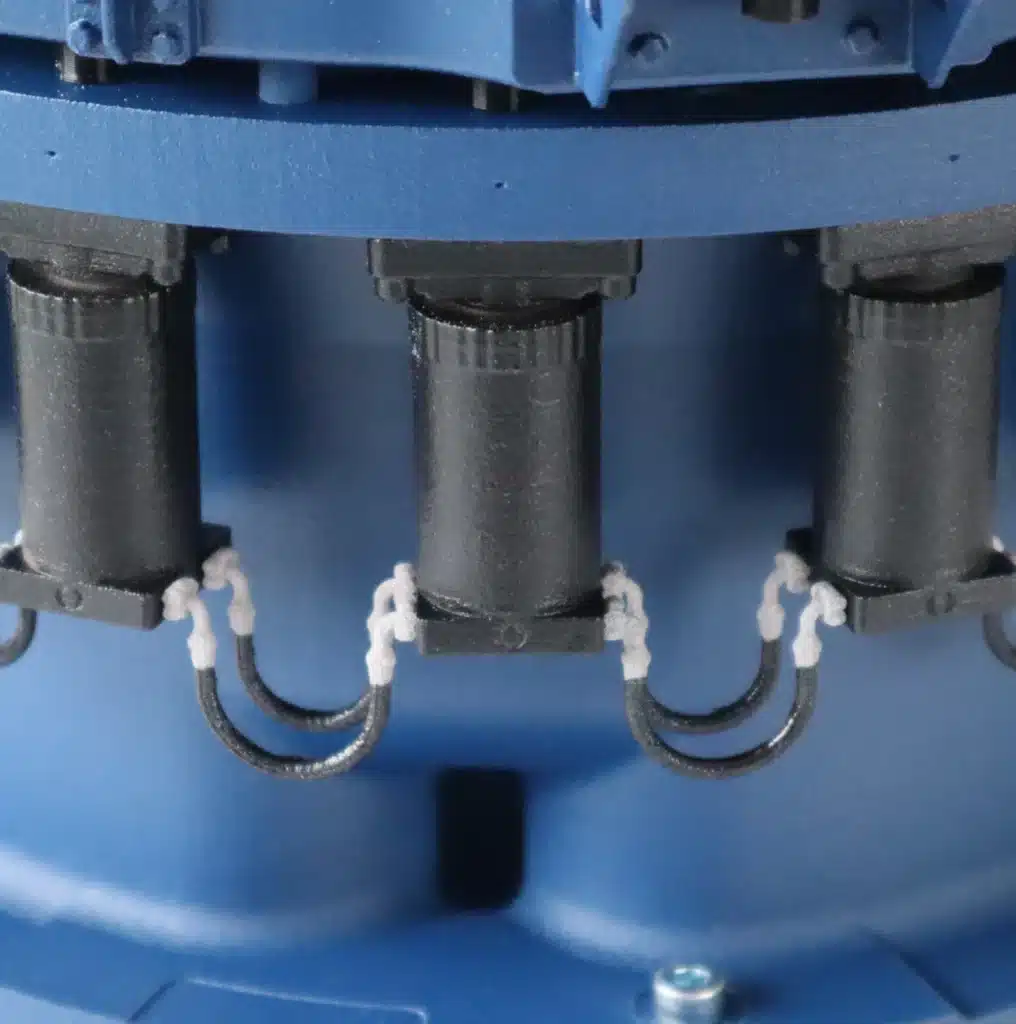

Scaling down shouldn’t mean you have to compromise on getting the details as well. The model should represent the original item as closely as possible and we take great care to include it all.

By respecting logo design and colour schemes, we make sure that your model won’t be mistaken for anyone else’s equipment

PRINTbart specializes in creating 3D printed assemblies with a high degree of detail which facilitate a better understanding of the functionality and features of your equipment.

Be it safety, ease of operating or anything else, use the model to underline whatever design features you think matters most to your clients.

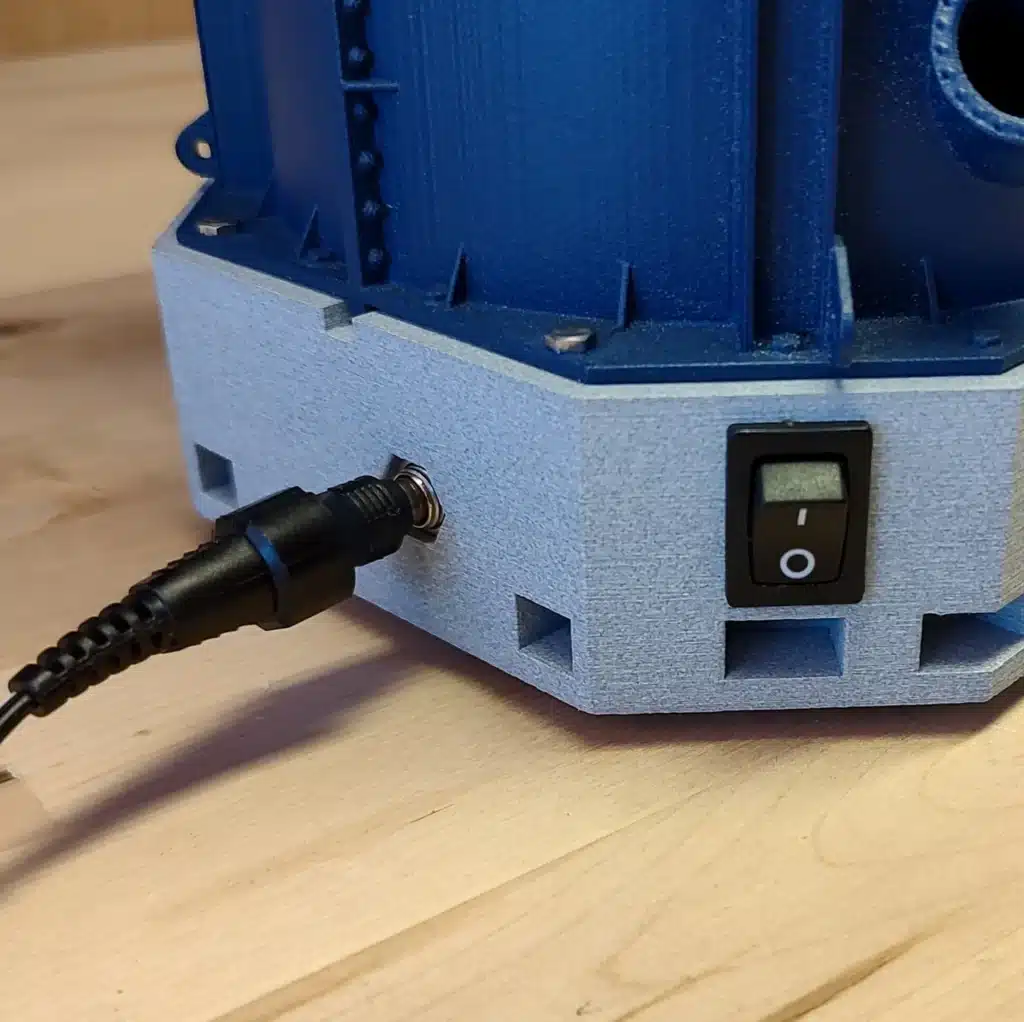

Why not add some functionality to your model? This can for example be adding LED lighting, DC motor for moving parts, magnetic assemblies or anything else that might assist you in promoting your product by replicating the real article.

PRINTbart specializes in creating 3D printed assemblies with a high degree of detail which facilitate a better understanding of the functionality and features of your equipment.

If the real magic is happening on the inside of your product, then a sectioned-cut is a brilliant way to reveal the construction and operating principles of your equipment.

Model assemblies can be designed to be separated, just as they would be in real life. By doing this, it is possible to show maintenance procedures and even perform faultfinding or troubleshooting when an issue occurs.